Milling Machine: Operations With CNC Milling

Many operations can be performed in connection with milling. They will determine what type of action the cutter will take on the part being developed? Depending on how the machine works, we can talk about different processes. The best-known are drilling milling, engraving milling, face milling, casting milling, sample surface milling, rotary surface milling, and bevel surface milling.

Of course, we are not talking about that a piece is better believed one way or another, but rather, depending on the designer’s goal, one or another milling must be done. For example, expecting a flat piece is not the same as one with curves or teeth. Each shape and design have its steps and tools.

Differences Between A CNC Milling Machine And A Conventional One

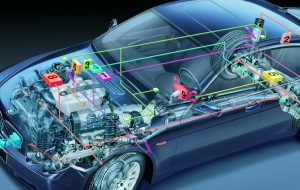

If we compare the process with a conventional milling machine and a CNC, we will find that there is greater control when the latter is handled. This is because the computer allows movements with a precision that would not be possible manually. Among them are diagonal lines, circles, and complex three-dimensional figures. The strangest thing is that it is not a worker who does this work from the computer; he has to program the operations with numerical codes. So, they walk alone.

With the milling machine (เครื่อง กัด which is the term in Thai) speed and position of the motors are controlled. These are responsible for driving the machine axes. It also starts moving the table and spindle. In this way, all parts of the production are uniform, which increases the quality and precision of the end product. What are the advantages of milling: Advantages of vertical and horizontal milling?

Directly after the drilling machine and the lathe, the milling machine is one of the essential machine tools for the manufacturing industry. A key difference between a lathe and a milling machine is that the former has single-point cutting tools, while the latter has multipoint cutting tools. Milling is nothing more than the process of removing metals bypassing the workpieces through a rotating multipoint cutter.

The machine can hold multiple cutters at once, and it operates at high speed for faster metal removal. The removal rate on milling machines is faster than on lathes.

The benefits of milling don’t end with speed, however. Before we dive into the types of milling and the benefits that come with them, let’s take a look at the general advantages of milling.